Tailor-made solutions in small quantities or small batches, functional integration and bionic design the benefits of additive manufacturing are widely recognised. The question remains: how can additive manufacturing be used for large components where conventional 3D printers reach their limits in terms of space and flexibility? In the ZAL R&T department, a small interdisciplinary team consisting of AM and robotics experts is working on answers. Their goal: not only to meet the existing demand for large 3D printed components, but also to identify new areas of utilisation together with other aviation partners.

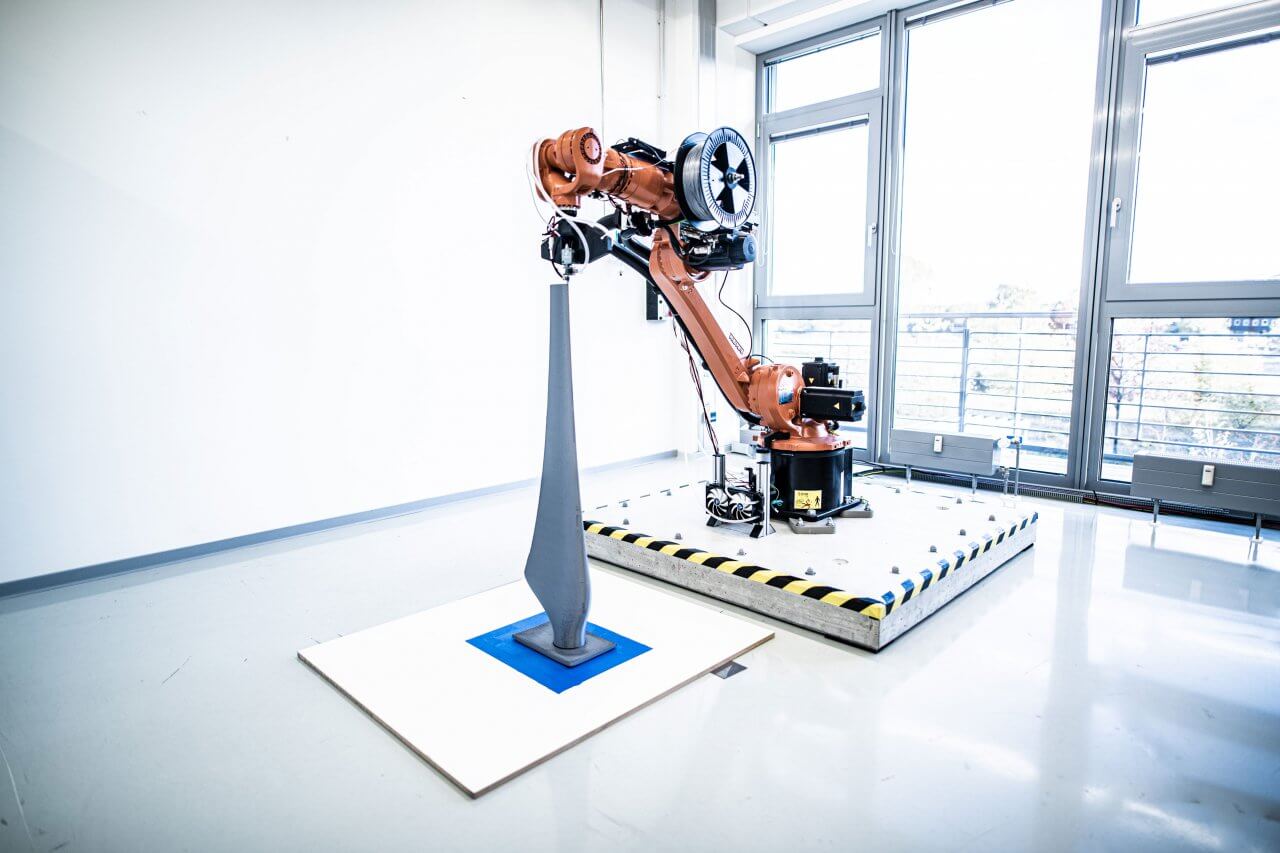

The solution developed by ZAL’s R&T department is an open test stand based on Robot Guided Additive Manufacturing. Printing is performed by a fully automated industrial robot equipped with a mounted print head. A specially developed central control concept regulates and monitors the test stand’s operation. This in house-designed test stand enables engineers to print components several cubic meters in volume. Further benefits include the ability to print on curved surfaces due to the flexible movement of the print head-mounted robot; a process difficult to implement using conventional printing methods, as well as retaining both the process speed and construction quality we have come to expect from conventional 3D printing.

The current development status is impressive: in terms of time, a linear surface speed of 80mm/s can be achieved, as well as a PLA-based build-up rate of 30cm³/h. The plastics used are PLA, PC and ABS (polylactides, polycarbonate, acrylic-butadiene-styrene). Notwithstanding this success, development is set to continue: High-temperature components as well as the application of heat to the production area should enable the use of high-performance plastics in the near future.

The construction of the plant and its testing with high-performance polymers are funded by the Federal Ministry of Economics and Energy as part of the LuFo V-3 aviation research program.

Click here for an insight into Robot Guided Additive Manufacturing.

If you would you like to learn more please feel free to contact us!

Additive Manufacturing

Dr.-Ing. Thorsten Scharowsky

Senior Development Manager

+49 40 248 595 132